Letter from the Director

The 2022-2023 Academic Year has been a year of celebration. The College of Agricultural Sciences and Natural Resources (CASNR) is celebrating 150 years of existence. The University of Nebraska Institute of Agriculture and Natural Resources (IANR) is celebrating its formation that took place 50 years ago. The Food Processing Center is celebrating its creation 40 years ago with an event scheduled for June 9th. Not to be forgotten in the excitement is recalling that the Department of Food Science and Technology was officially formed out of the Department of Dairy Technology and several food specialists from other departments 55 years ago on February 1, 1968.

The Department also celebrates Dr. Amanda Ramer-Tait being awarded the Office of Graduate Studies Dean’s Award for Excellence in Graduate Education and the nominations of other faculty members for IANR, CASNR and Agricultural Research Division awards. Additionally, promotion of Dr. Yanbin Yin to Professor and promotion of Dr. Kaustav Majumder to Associate Professor with continuous appointment are to be celebrated.

A total of 39 undergraduate and 30 graduate students completed their degree programs over this past academic year. Generous financial support to 12 Food Science and Technology-associated funds of the University of Nebraska Foundation benefited many of the graduating undergraduate students. In fact, this past year, 23 undergraduate students were the recipients of $72,750 in scholarship funding. A special thanks to those who contributed and to those who continue to provide support.

Over the past year, the Department collaborated with the Department of Animal Science in transitioning of the Food Technology for Companion Animal major to a minor with the same name. The Department also led in the development and securing of approval for a Fermentation Science minor. Both minors will become available to students beginning in the fall of 2023. It is anticipated that the minors will provide new pathways for students to take advantage of the numerous opportunities that exist today in food and beverage organizations.

You are always welcome to stop by at the Food Innovation Center. I would be pleased to give you a tour the next time you make it to Lincoln.

Curtis L. Weller, Ph.D., P.E.

Professor and Head, Department of Food Science and Technology

Director, The Food Processing Center

FPC 40th Anniversary with Executive Director Dr. Terry Howell Executive Director of the Food Processing Center Terry Howell reflects on 40 years of the Food Processing Center, what’s been achieved, and what’s in store for the future.

Established in 1983 and approaching its 40th anniversary, the Food Processing Center within the Food Science and Technology Department was constructed to meet the needs of a diverse set of food industry clientele in Nebraska. Everyone from entrepreneurs looking to start selling their homemade recipes on a larger scale to established manufacturers, suppliers, distributors, associations, and retailers have utilized the FPC’s expert scientists and state-of-the-art facilities.

Moreover, the FPC provides an unparalleled array of experiential learning opportunities for Food Science and Technology students, setting them up for success in their careers.

Dr. Terry Howell joined the FPC as Executive Director in 2018 and has gotten to admire the FPC’s wide-ranging impacts up close as he prepares to celebrate its 40th anniversary. As Executive Director, Howell oversees the full spectrum of FPC’s operations, from working with local entrepreneurs to household corporate brand names and training student workers to set them up for careers in the industry.

“I help coordinate all the activities of the FPC, supervise and support staff, and help set strategies and goals,” explains Howell of his role. “Mainly, I make sure that we’re serving the needs of the people of Nebraska, the region, and wherever else our clients are based.”

For the 40th anniversary, Howell and others in the FPC are planning a June 9th, 2023 celebration at the Food Innovation Center on Nebraska Innovation Campus to acknowledge the accomplishments and efforts of all those who’ve worked with and impacted the FPC since 1983.

“We’re going to bring together the FPC community that’s been affiliated with the center and the food science department, drawing former staff and student employees, Nebraska food industry professionals as well as industry professionals from around the region who’ve been impacted by our work,” says Howell.

“It’s a chance to highlight and celebrate 40 years of serving the food industry of Nebraska, recognizing the accomplishments of those who have come before us while also looking forward to what we want to accomplish in the future.”

As anyone involved in the FPC’s 40-year history will tell you, the center’s focus on educating and fostering bright young talent in the field of food science is among the chief points of pride for the FPC and food science and technology department. Howell is especially proud of this aspect, noting its distinguished history of placing students in career-launching internships.

In the summer of 2022 alone, students working in the FPC earned internships in Washington, Utah, North Carolina, and Los Angeles.

“We’re very intentional about making sure that students have valuable experiential learning at the FPC. Having a working dairy plant lets students learn firsthand not just how ingredients interact together, but also how laws and regulations impact the industry,” says Howell of student involvement in the FPC’s operations.

“They’re actually doing rather than observing, learning and growing and making themselves more valuable to the industry when they graduate.”

Looking ahead, Howell is confident that the FPC will continue to innovate and adapt to an ever-changing industry in the same way it has the last 40 years. Pet food, for instance, is an area of increased demand in which Howell sees an opportunity for the FPC to continue making headways.

“30-40% of our current projects are in the pet food space. We see a high demand there, so making sure we have the proper equipment and that our students are getting trained for that will be very valuable for the future of the center and our students.”

Head to fpc.unl.edu/40 to stay up to date with the Food Processing Center’s 40th Anniversary celebrations.

Ciftci’s Research Pioneers Green Technologies in Food Engineering The work of Dr. Ozan Ciftci, Kenneth E. Morrison Distinguished Professor of Food Engineering in the Food Science and Technology Department at UNL, exists on the cutting edge of innovation and sustainability.

With a unique background combining chemical engineering, food processing and lipids research, Dr. Ciftci has embarked on a mission to develop novel green technologies for food processing while focusing on improving food quality, human health and environmental sustainability. Dr. Ciftci’s pedigree and research efforts are an invaluable contribution to the Food Science and Technology Department, continuing the department’s tradition of state-of-the-art research and worldwide leadership in the field.

“Our ultimate goal and vision,” says Dr. Ciftci, “is what I call a green revolution in food engineering: creating quality food, healthier people and a healthier environment.”

Central to Dr. Ciftci's research is the development of green technologies for food processing. By harnessing the power of supercritical carbon dioxide, a safe and environmentally friendly solvent, he strives to improve food quality while reducing the use of toxic or hazardous substances.

“Many current technologies in lipid processing require the use of toxic or dangerous petroleum-based solvents,” he explains. “Even though we do not directly consume them, they’re bad for the environment and are still in contact with our food.”

Dr. Ciftci's lab focuses on creating simple and clean technologies that not only enhance food processing but also lead to the production of advanced food products with improved quality, extended shelf life, and enhanced health benefits.

“We’re developing our own green technologies, and at the same time those technologies are generating novel food materials with advanced properties that are superior to their counterparts.”

Dr. Ciftci's journey in food engineering began in Turkey, where he pursued a degree in food hygiene that nurtured a deep passion for research and lead to a master's and Ph.D. He then moved onto postdoctoral work in Canada delving into lipids, focusing on bioresources and food engineering before joining the UNL Food Science and Technology Department as a faculty member.

“I was very impressed with the people and the facilities at UNL,” recalls Dr. Ciftci. “They were already doing research on lipids, but it was mainly focused on chemistry. I was combining chemistry and engineering — and later nutrition and health aspects — so I saw that there was room to grow my research and the program here at the same time.”

In the field of food science and technology, lipids have long been a focus of research. However, Dr. Ciftci recognized the untapped potential for innovation in the area of food lipids. Combining his expertise in liquid chemistry, processing and engineering, Dr. Ciftci aims to push the boundaries of lipids research in a way that integrates nutrition, health, and engineering aspects, with a particular emphasis on the processing of lipids using supercritical fluid technologies that puts UNL a cut above peer institutions.

“We’re still unique in the area of supercritical food technologies,” says Dr. Ciftci, “and I knew I could help take that research to the next level.”

Recognizing that the health benefits of food extend beyond its ingredients, Dr. Ciftci emphasizes the importance of engineering aspects such as processing, storage, and packaging. The Food Science and Technology Department’s vast array of specialties and resources — such as the Food Processing Center — allow for Dr. Ciftci’s work to take a collaborative approach in the department.

He cites both the faculty and students at UNL as being crucial to this cross-disciplinary work.

“The health benefits of food don’t only come from its ingredients, but also how you process it, store it and package it,” he explains. “Students are critical in this work. Without the postdoctoral students here in the lab, we couldn’t run our programs. We have amazing students here.”

Freeze Drying Capabilities an Advantage to FPC's Industry Partners Russell Parde, the General Pilot Plant Manager of the Food Processing Center (FPC) located on Innovation Campus, plays a pivotal role in the success of the Food Science and Technology Department. He highlights the FPC's newest freeze dryer as a massive asset to the department and its partners.

In his position as the Pilot Plant Manager, Parde oversees client communications and manages the trials requested by industry partners, finding practical solutions that align with the available equipment and staff resources. With 80,000 square feet of processing facilities housing a diverse range of equipment and services, Parde ensures the smooth operation of the pilot plant while meeting the needs of clients.

"Most of our work is for industry clients who contact me seeking assistance in achieving their goals or trying out new ideas. We also collaborate on various graduate student projects," says Parde of the FPC, which will celebrate its 40th anniversary this summer.

"We have something to offer for everyone."

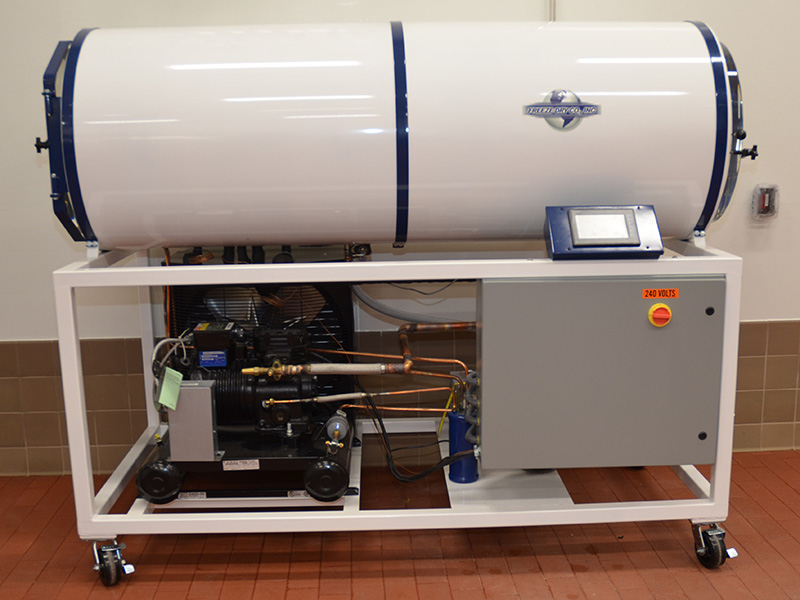

While the FPC encompasses a wide range of capabilities, including extrusion, high-pressure processing, and even a brewery, freeze drying has emerged as a significant focus for the center. While small freeze dryers have been part of the center's equipment for over two decades, the recent addition of a large freeze dryer has significantly expanded their capabilities and flexibility to meet diverse market demands.

"We work with products ranging from bison liver, used for nutraceutical capsules, to freeze-dried berries and vegetables ready for cooking," explains Parde. "Many of our co-manufacturers require freeze drying; it's a rapidly growing market."

The increasing popularity of freeze-dried products, he notes, can be attributed to consumer demand for clean-label options that retain the nutritional qualities of fresh produce.

"Consumers want clean labels with the nutritional benefits of fresh products, along with the convenience of dried goods that can be stored on shelves or in freezers."

According to Parde, large manufacturers may require minimum batch sizes of several thousand pounds, making the FPC an attractive option for clients who prefer to start with smaller quantities.

"Our ability to handle low minimum quantities sets us apart, and our additional processing capabilities, such as fruit slicing, are appealing to clients," says Parde. "We have a wide range of extra equipment that can accommodate various products."

The FPC's diverse range of industry applications and in-demand services give student workers a competitive advantage when entering the workforce or applying for internships. Parde, a former student worker himself, takes pride in the FPC's culture of empowering students to develop a comprehensive understanding of the field.

"Students rotate across the center, assisting with product development, bench top work, the dairy plant, and helping prepare studies for sensory analysis," he explains regarding the different aspects of student work in the FPC.

Importantly, these students have the opportunity to gain hands-on experience with freeze-drying processes.

"We're currently preparing to mill down the freeze-dried bison liver into a powder, and I have a student worker assisting me with the milling — and that's really exciting."

Undergraduate Spotlight: Introducing Senior Andre Chavez The Food Science and Technology student from San Antonio, TX has been a staple of the Food Processing Center during his college career. Now in his senior year, Andre’s preparing to take those experiences out into the real world.

Andre has always enjoyed cooking – tweaking and experimenting with recipes ever since he was a kid. Still, as he began to think about college, Andre never felt that culinary school would be the right fit for him. He found himself searching for ways to stay close to the food industry without having to become a chef or work restaurant jobs.

That’s when Andre learned about UNL’s Food Science & Technology program and about the Food Processing Center.

As a food science and technology major working in both the Food Processing Center and the Dairy Lab, Andre has been able to follow his creative culinary passions while also accumulating extensive industry experience. Andre's cooking talents have especially been an asset to Food Processing Center’s Product Development Lab, which helps clients develop and formulate recipes or improve on existing ones for an array of products.

“My experience with and love for cooking has been an advantage for my managers and others at the Food Processing Center,” says Andre. “They have more of a science background, but I have this culinary knowledge that has helped in terms of evaluating flavor, texture and finding different ways to bake things.”

In the Product Development Lab, Andre has had the opportunity to work on the ideation, formulation and delivery of food products, ranging from sauces and puddings all the way to cereals, coffee products and potato chips.

Andre loves being able to help amateur chefs and culinary tinkerers take their ideas to the next level.

“We get a lot of clients that are just making food for their friends and want to see if they can mass produce it. We’ll help them do things like choose preservatives or test the shelf life,” describes Andre. “We help them transfer from the small scale into large scale.”

This experience in product development played a huge role in Andre landing an internship for the prominent food science company Ingredion in Oregon over the summer of 2022. And not only did it help him land the internship, he says, but his strong foundation also helped him hit the ground running once he started.

“In a lot of ways, it was really similar to the work I’d been doing in the Food Processing Center. I think it both helped prepare me for the internship but also helped me secure the internship in the first place,” describes Andre. “Everything in the position already felt very familiar to me.”

Andre also credits his preparedness for his real-world experiences in the food science industry to his time working in the Food Processing Center’s Dairy Lab.

“The Dairy Lab has given me a lot of experience in an actual production setting – it’s like a small-scale plant,” says Andre. “That definitely made me more prepared for my internship in Oregon – they had a plant attached to their labs and I was already comfortable working with that large equipment.”

Looking ahead to graduation and beyond, Andre knows that his time working in the Food Processing Center has left him more equipped than most to enter the industry.

“I know that even after I leave, I can still reach out to my managers and the president of the FPC – they’ve been a great resource for me and have given me some amazing networks.”

PhD Candidate Haque Explores New Frontiers in Food Safety In the field of food safety, the importance of experts that work to understand and mitigate risks that could compromise the health of consumers cannot be overstated. PhD candidate Manirul Haque is pursuing a doctorate in the Food Science and Technology Department to address these important public health concerns and prevent foodborne illness.

Hailing from Bangladesh, Haque brings to the Food Science and Technology Department an array of insights and a profound desire to contribute to the field of food safety.

“If you want to prevent an outbreak, you have to understand the transmission of different microbes and how they make people sick,” explains Haque. “We’re studying the interaction of different microbes and trying to understand how it would transmit from food products to humans.”

By studying these interactions, Haque aims to unravel the mechanisms behind microbial transmission, shedding light on how pathogens can cause harm to consumers.

“If we understand growth rate and transmission, we can effectively establish and control the status of different specimens, which contributes to preventing outbreaks.”

Haque’s mission to prevent foodborne illness and outbreaks is rooted in his wide-spanning background and professional experience in food science.

He first obtained a bachelor's degree in Fisheries and Aquatic Biology, followed by a master's degree in Seafood Safety. Working in the food safety sector exposed Haque to the challenges faced in ensuring the safety of seafood products. Organizing training programs for national and international stakeholders, including government officials, processing plant workers and chefs, he learned firsthand the importance of continuous training and up-to-date practices in the field.

“During this time, I came to understand that more training was necessary to learn more about food safety,” recalls Haque. “I wanted the opportunity to increase my knowledge.”

This desire to go deeper into food safety brough Haque to the United States in 2016, enrolling in the Food Science program at Mississippi State University for a master's degree. Driven to continue his education and fulfill a lifelong dream of earning a PhD, Haque sought a program that allowed him to delve deeper into the microbial aspects of food and sought admission to the Food Science program at UNL.

“I applied to UNL knowing that it was a very renowned department in the food science and food safety community,” says Haque. “I understood that I could learn more about microbes by coming here.”

In his research, which focuses on studying pathogenic E. coli and its potential as an emerging pathogen in pork products, Haque aims to contribute to the prevention of E. coli outbreaks and the mitigation of foodborne illnesses by unraveling how the bacterium can survive and potentially infect consumers. His work looks at how effective control strategies can be established and lead to safer food practices.

Haque credits the expertise of the faculty he works under in the Food Science Department, the state-of-the-art lab facilities and, especially, the warm, welcoming culture inside the department as being instrumental to the ongoing success of his PhD work.

“The people in the Food Science Department have been amazing during my time here at UNL. It’s been a very inclusive culture; I and other students feel very comfortable working together in these facilities.”

Looking ahead, Haque aspires to bring his expertise to the industry, recognizing the need for specialized knowledge in food safety. Having already completed an internship with Conagra working on food safety, Haque feels prepared to combine the academic and experiential learning opportunities he’s garnered at UNL and bring his skillset into the workforce.

“My hope is to help people — the knowledge I’ve gained from UNL is something I want to spread to others. I know that not a lot of people in the industry have PhDs in this field, so it’s creating a lot of opportunity for me.”

Where Are They Now? Alumni Spotlight Alumni David Schroeder looks back on how his experiences in the Food Science and Technology Program and Food Processing Center have shaped his professional career.

Nearly 20 years after graduating from the Food Science and Technology program at UNL, alumni David Schroeder still has plenty of time to sing the praises of his alma mater and home state. Now a Senior Principal Scientist in Separation Sciences for The Kraft Heinz Company in Illinois, Schroeder remembers the names of faculty, staff and mentors – as well as the hands-on learning experiences in the Food Processing Center – that helped him get to where he is today as clearly as if he were still an undergraduate student.

Suffice to say, Schroeder has a special affinity for Nebraska.

“People ask me what I love about Nebraska, and I say well: the people are sincere, they will tell it like it is, and they have a sense of community that I just haven’t seen elsewhere.”

This sense of community, particularly in the Food Science and Technology department, is what propelled Schroeder to a graduate and doctoral degree at Purdue, a yearslong position working for the EPA, and eventually to his current role at Kraft Heinz.

“The faculty and staff in the Food Science and Technology Department are great. They genuinely care about what you’re interested in and helping others,” recalls Schroeder, noting that this attention to every student helped him assimilate easily after coming to UNL from the small town of West Point, NE.

“I came from a class of 50 at a school near Bilger to UNL – which is not small – and it still felt like you could go anywhere and ask for help. Everyone in the food science department was so warming to me.”

From an early age Schroeder knew that he loved food, getting involved in Nebraska 4H and FFA that exposed him to food and agricultural production and the industries surrounding them. This, combined with an aptitude for chemistry, helped Schroeder identify UNL as the perfect place to build on the foundations he received growing up.

Now, sitting in a mass spectrometry lab in Kraft Heinz, Schroeder says he’s still pulling from his knowledge base and experiences he received from UNL.

“I don’t want to make it sound like a stepping stone – my experience in Food Science and Technology and in the Food Processing Center gave me skills that I still use today,” asserts Schroeder. “They have world-renowned leaders that are nice and approachable.”

He says that he and his colleagues at Kraft Heinz regularly consult experts in the Food Allergy Resource and Research Program in UNL’s food science department.

“Everybody in the industry knows that if you have a question about allergens and want the facts, you go to FAARP.”The Food Processing Center, he says, has equipment that even companies like Kraft Heinz need to leverage for their own needs.

“They have equipment like extruders where even companies like ours don’t have that pilot scale and will have to go somewhere like the FPC,” he says, adding that his time working at FPC exposed him to areas of the industry also still resonate into his professional career.

“Getting to work at the FPC with the amazing faculty and staff on everything from small ingredient manufacturing to dealing with large companies and multibillion-dollar brands was a joy. It gave me amazing experiences.”